Abstract:

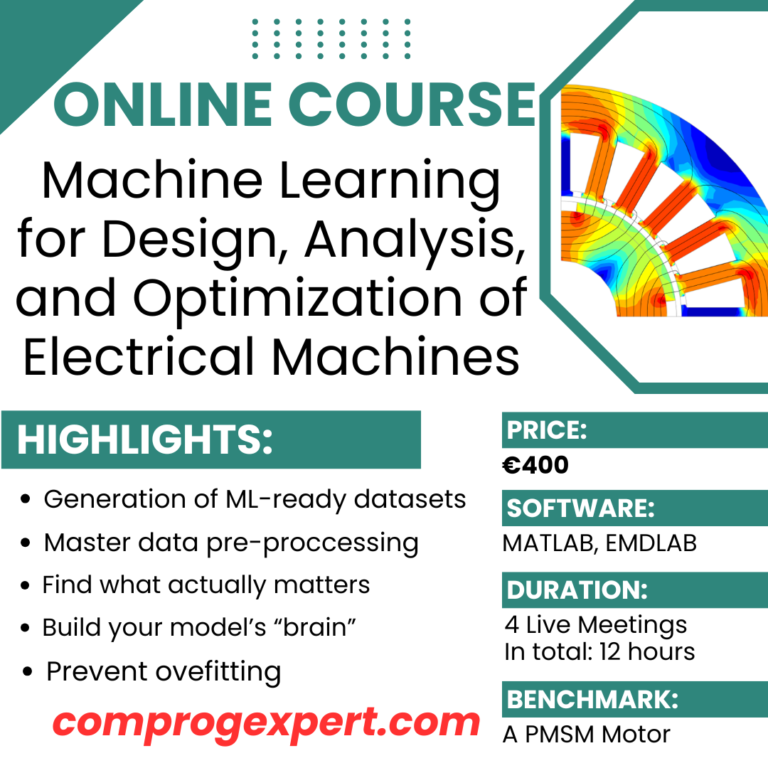

Master the complete workflow, from FEA data to deployed neural networks, and accelerate your design cycle. Join the 4-session workshop that teaches engineers how to model electrical machines’ performance using MATLAB and ML (no prior AI experience required).

Course Contents:

Go Beyond FEA: Understand why traditional “white-box” analytical models are slow and how to build “black-box” ML models that capture complex physics and deliver predictions in seconds.

Generate ML-Ready Datasets: Learn to extract data from FEA software. Master smart sampling techniques (like Latin Hypercube and Full Factorial) to create robust datasets that cover your entire design space.

Master the Data Pre-Processing Workflow: Get hands-on in MATLAB to load, clean, and visualize raw engineering data. Learn to identify and handle the outliers and missing data that corrupt real-world simulations.

Find What Actually Matters: Stop guessing which design parameters are important. You’ll implement systematic feature selection strategies (like the wrapper method) to scientifically prove which inputs most influence your model’s performance.

Build Your First “Digital Twin”: Apply your skills immediately with practical, hands-on exercises, building a performance model of the motor using a benchmark dataset.

Train & Configure Neural Networks: Build the “brain” of your digital twin by mastering the two most common neural networks for this work: Multi-Layer Perceptrons (MLPs) and Radial Basis Function (RBF) networks.

Prevent Overfitting: Learn to build models you can actually trust. You’ll master the critical process of splitting data into training, validation, and test sets and use “early stopping” to prevent overfitting.

Deploy & Accelerate Your Workflow: Use your final, trained model as a high-speed tool to perform instantaneous parametric studies, rapidly analyze thousands of design variations, and make innovative engineering decisions without the wait.