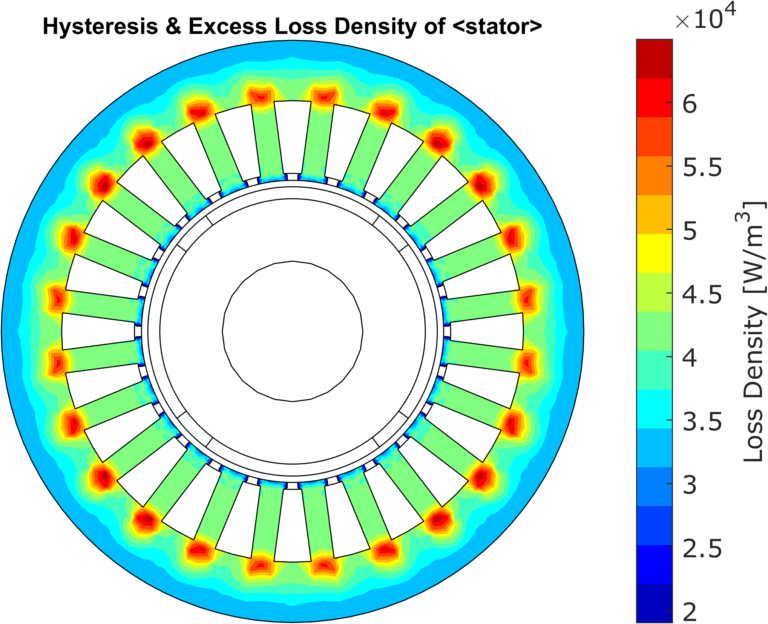

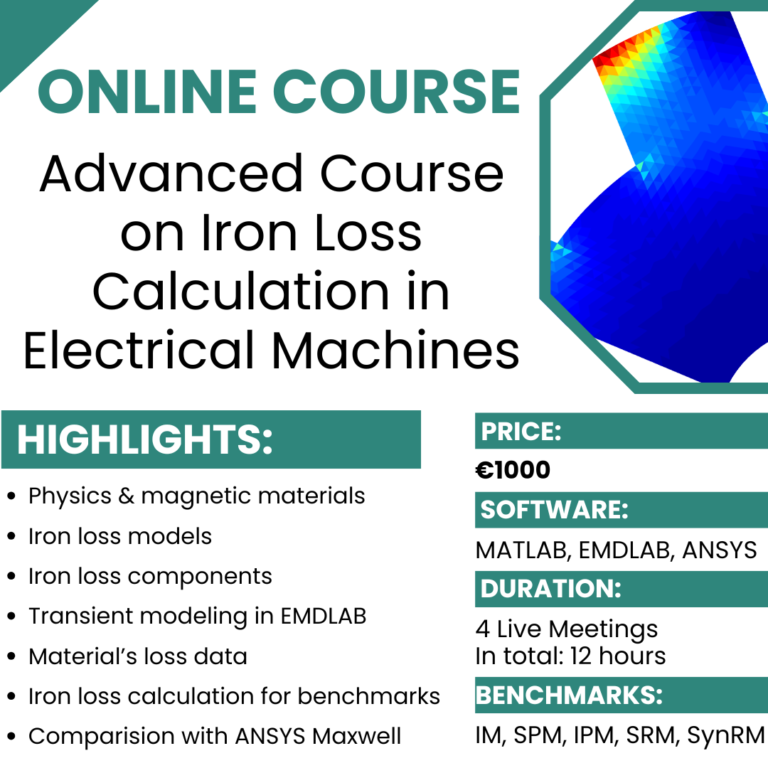

Iron loss calculation in electrical machines is a complex task because it depends on several interacting phenomena, including nonlinear magnetic material behavior, rotating and alternating flux components, space and time harmonics, and local saturation effects. Various methods have been proposed for iron loss estimation, ranging from simple analytical models based on Steinmetz-type equations to more advanced approaches that separate hysteresis, classical eddy current, and excess losses using experimentally identified coefficients. While analytical and lumped-parameter methods are computationally efficient, they often fail to capture local effects such as flux rotation, tooth-root saturation, and harmonic-rich excitation. The finite element method (FEM)–based iron loss calculation provides a more accurate framework by resolving the spatial and temporal distribution of magnetic fields within the core. However, this approach significantly increases complexity, as it requires recording the magnetic field quantities on the mesh over time and performing detailed post-processing to evaluate loss density at each element. In EMDLAB, this workflow is fully supported, allowing users to store field data and compute iron losses through dedicated post-processing tools, and the implementation and practical use of this FEM-based iron loss calculation constitute one of the key topics covered in this course.